How automotive component suppliers can use predictive pricing to stop eroding margins

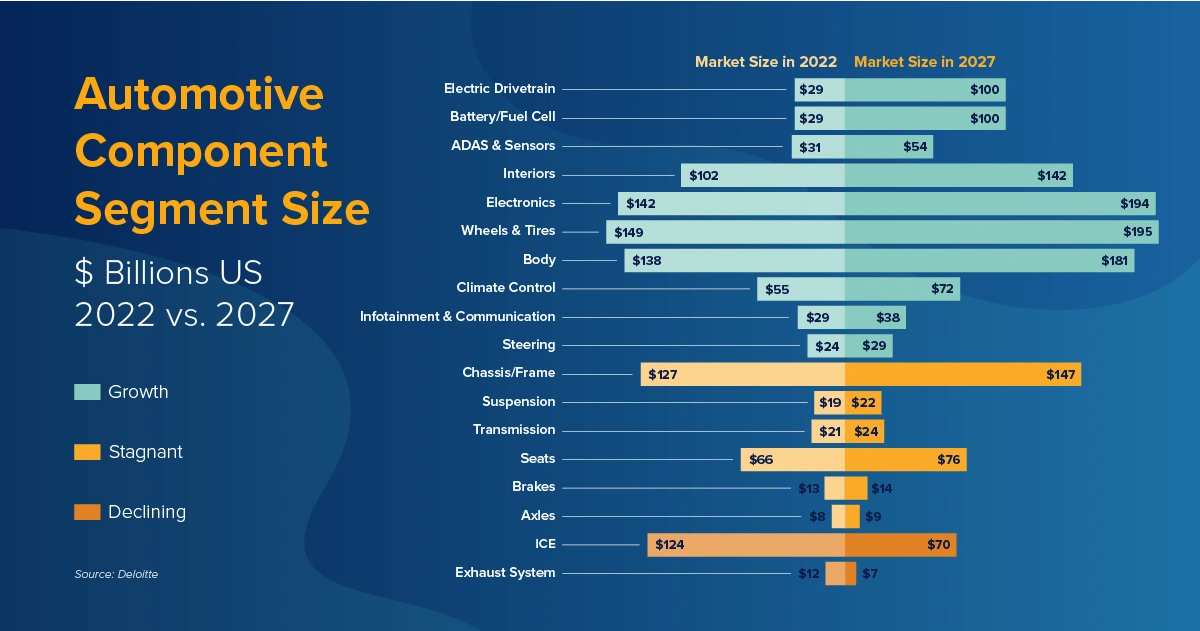

It’s no surprise that the rising tide of autonomous technologies and electric vehicles (EV) has created ripple effects in the downstream supply chain, especially for automotive component suppliers. Traditional component manufacturers, such as drivetrain suppliers, have invested heavily in the electrification of their products in the past few years. At the same time, market uncertainty brings increased complexity in production and the need to be flexible in the face of changing customer product timelines. For example, EV sales growth has recently slowed, and some major manufacturers have announced significant delays in launching new EV platforms and autonomous vehicle technologies.

Headed for a Wipe Out?

Component suppliers are also facing greater economic challenges due to inflationary levels causing higher costs for labor, materials and energy. To make matters worse, automakers have not been accepting price increases for components and will most likely continue to put pressure on suppliers to meet aggressive price targets. All of this has resulted in eroding margins for companies like yours.

The average car contains thousands of parts – from the smallest screw to the largest engine block. Component suppliers represent the largest segment of the industry and greatly outnumber vehicle manufacturers. If the current tsunami of challenges is not addressed, we could see further negative consequences around available capital and funding for R&D, at a time when the industry needs a healthy and productive components segment.

It’s Time to Shred

The good news is that there are several proactive measures that you can take to improve the situation:

- Negotiate with customers to pass on some of the increased costs

- Shorten payment terms and eliminate discounts for early payments

- Continue to look at new ways to reduce operating costs, such as enhancing revenue management processes to improve bottomline results

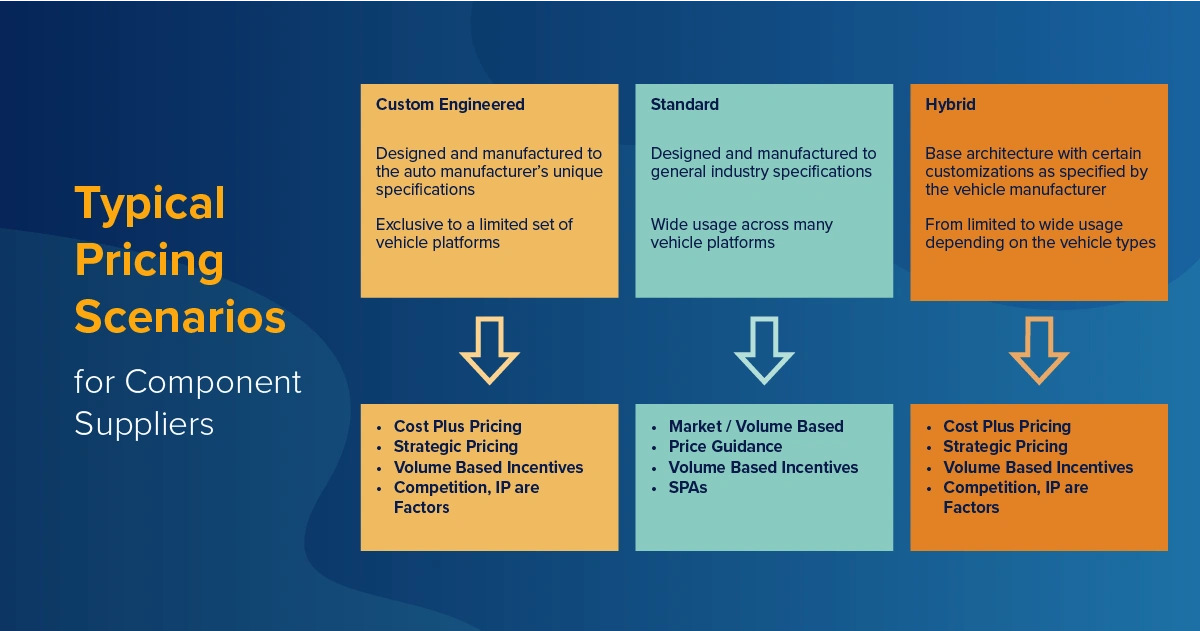

Taking a data-driven approach toward pricing strategies will help suppliers like you respond faster, maximize margins and win new business. Just as lean manufacturing principles take the waste out of production processes to become more efficient, revenue management systems help do the same by automating revenue calculations. As a result, you can proactively propose better prices and promotions, as well as track rebates, reimbursements and expenses for intellectual property.

Achieve Gnarly Margins

Some benefits that component suppliers can achieve with predictive pricing:

- Eliminate the time-consuming and labor-intensive manual process of setting and updating prices along with the ability to scale company-wide

- Reduce errors and inefficiencies inherent in using spreadsheets or disconnected systems

- Data science and analytics can provide insight and help you review market alignment, plan for price optimization and identify products with price elasticity

- Enable future contract performance with pre-deal analysis

- Ensure comprehensive cost control on every level with self-service reporting

- Compare side-by-side Gross-to-Net profitability between customers and across products

If your margins are eroding like the tides and your business involves a lot of complex pricing scenarios, multiple variations of similar components, rebates and incentives, or if you process pricing adjustments with claim backs for commodity or freight price fluctuations, then revenue management may be just the thing you need to become the Big Kahuna of the industry.

Gain greater visibility and control of your revenue management systems

Get the latest news, updates, and exclusive insights from Vistex delivered straight to your inbox. Don’t miss out—opt in now and be the first to know!