No Hands, No Problem

How automotive Industry 4.0 can reduce waste beyond the production line

The concept of self-driving cars and taxis has been in the news for decades. There have been some successes, but the reality of self-driving isn’t right around the corner for your typical roadway driver. However, machines used in commercial applications have seen much higher adoption of automation and self-driving. These machines include agricultural tractors and combines, warehouse material handling, construction, and other off-highway vehicles.

Steering the future

If it wasn’t for the fact that combines and high horsepower tractors cost a half-million dollars and more, some farming operations wouldn’t even need a human in the cab to till, spray, plant, and harvest a field. Autosteer and guidance options are factory-installed for all newer high-end agricultural machinery. Aftermarket and OEM autosteer options are available for machines purchased without factory-installed autosteer and on many older machines. Precision planting and harvest can be accurate down to 2-½ centimeters with GNSS (Global Navigation Satellite System). In ag, the machine's speed and the tractor's tilt, combined on uneven terrain, are calculated with GNSS equipment for precision.

Skips and overlaps can cost a farmer thousands of dollars over a decade in fuel and lost productivity. A tractor or combine steering map can alternate every other row to reduce the inefficiencies a farmer might see with slowdowns at the end of rows and longer turn radiuses. The number of total passes can be reduced, and the most efficient map to plant a field can be plotted.

These auto-steer and guidance systems can integrate with other precision farming practices. Variable rate application (VRA) is a technology that changes the application of seeds, fertilizers and pesticides. As a machine travels through the field, that exact square meter that needs more or less of these inputs saves significant costs and improves efficiencies and yields. It’s pretty impressive, to say the least.

Automation in the driver’s seat

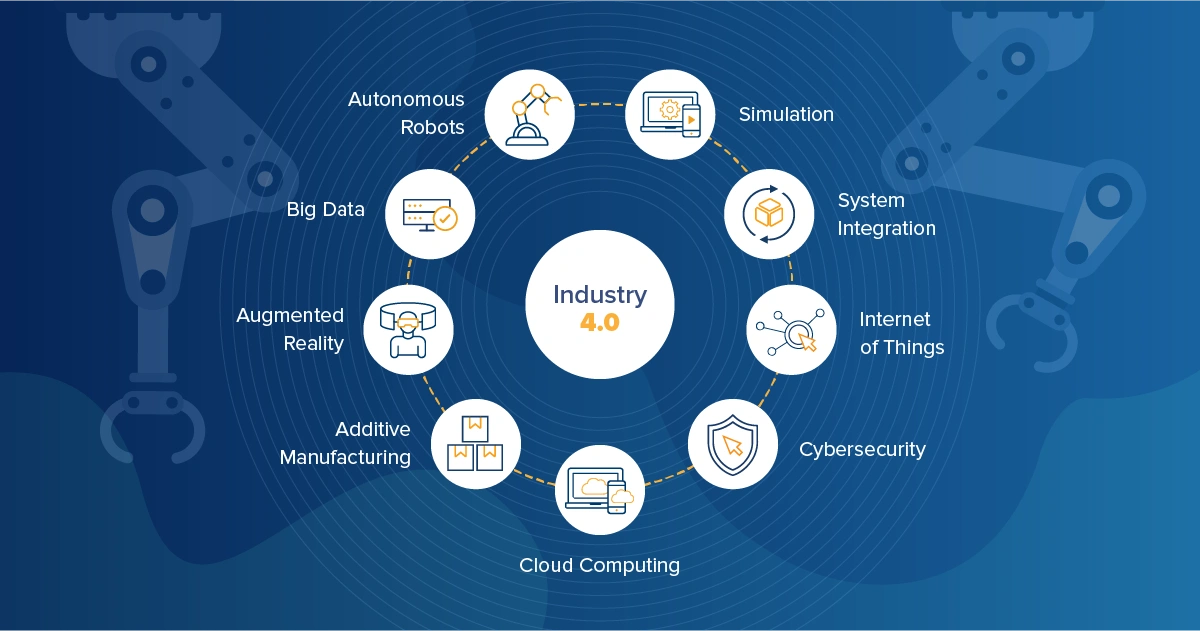

Today, automation is at the wheel—literally—in sectors like agriculture, logistics, and construction. This kind of transformation isn't limited to fields and farms—it’s part of a broader shift we know as Industry 4.0, the convergence of digital technologies—like IoT, AI, cloud computing, machine learning, and real-time analytics—with traditional manufacturing. It's about making operations more intelligent, faster, and more connected.

I believe this transformation of data-driven solutions that help automotive OEMs, agricultural equipment makers, and industrial manufacturers bring digital intelligence into every corner of their business isn’t optional—it’s essential. For example, I know a large orange juice producer fully digitized its farm operations with custom mobile and GIS-based applications, even when in offline environments. Field workers input data via mobile apps that sync with SAP S/4HANA. GIS heatmaps track disease outbreaks and harvest data with pinpoint accuracy. With enhanced tracking of machine paths, chemical application, and harvest data, the company significantly reduced waste and duplicated efforts.

This isn’t just about oranges—this is smart, scalable innovation that can be replicated in auto manufacturing, industrial production, and beyond.

Cruise control for success

For automotive manufacturers and ag operations, smart tech equals smart profit margins. Users can gain greater control of your operations by:

- Capitalizing on the investment smart technology provides for your business – from reduced material and input costs to fewer hours machines are needed in the field

- Managing complex pricing and cost models across global supply chains with transparency and control

- Unlocking analytics and insights that inform better decisions

- As you know, when your production line is more innovative, your bottom line follows. In a world where machines can drive themselves, shouldn’t your revenue-driving programs run smarter, too?

Learn more about automotive best practices for pricing, rebate and incentives.

Get the latest news, updates, and exclusive insights from Vistex delivered straight to your inbox. Don’t miss out—opt in now and be the first to know!